In addition to our wide range of welding alloys Selectrode manufactures a variety of proprietary welding related items to offer clients unique marketing advantages.

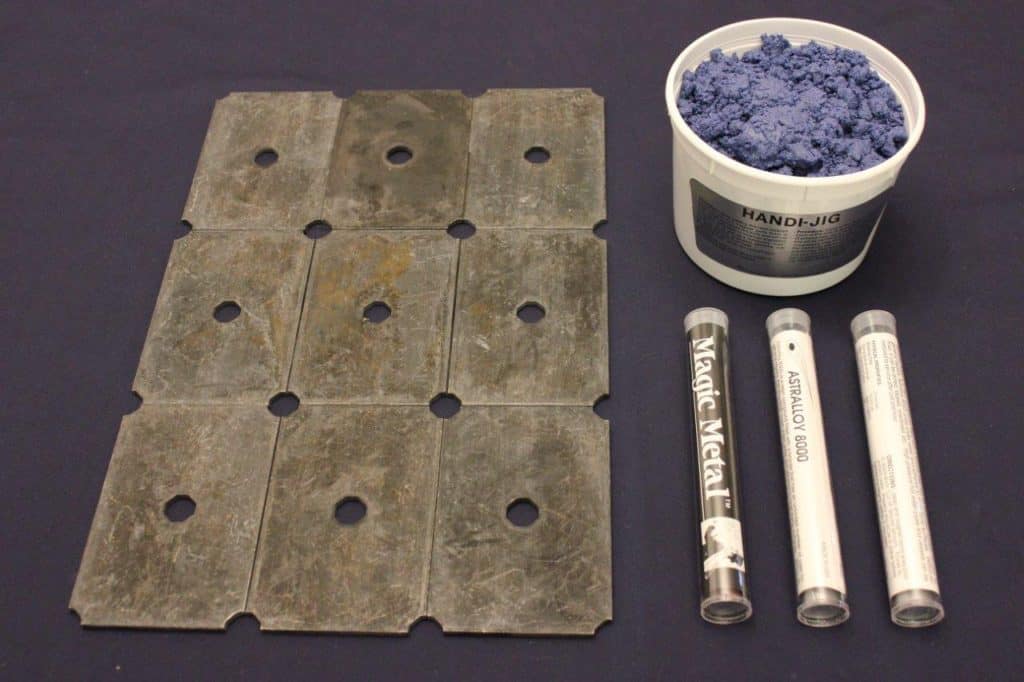

Diamond Disc Wear Protection System

Abrasive wear is the major contributor to downtime and costly repairs throughout industry worldwide. Smaller wear areas are easily repaired with our full line of wear resistant welding alloys. However large areas are too time consuming to efficiently repair with either manual or semi automatic wear facing techniques.

Subsequently, Selectrode developed a unique simple method to quickly repair not only large surface areas in need of overlay but also intricately shaped areas. The Diamond Disc Wear System utilizes a through hardened Rockwell C 60 alloyed steel plate that is further treated with a Black Chrome skin registering Rockwell C 72. Each disc is sized at 24 square inches (155 square centimeters) which allows the welder to apply hard surfacing at the rate of approximately 100 square inches (620 square centimeters) per minute. The shape of Diamond Discs allows for a pattern to form, when they are butted together, where the operator simply plug welds only the corners and center of 4 discs at a time. The weld attachment is accomplished with Selectrode product Diamond Join 1247 which is a joining electrode specially alloyed to work harden in service thereby also acting as a wear resistant surface.

Magic Metal Epoxy Stick

Magic Metal is an alloyed metallic epoxy resin that is extruded in the shape of a round stick. The center of the stick is the premeasured hardening agent which is activated by simply crushing or kneading a cut off piece of the stick in your hand. This design completely eliminates the risk of improperly measured epoxy components. Magic Metal is manufactured in 3 different alloy content types: copper, aluminum and steel. Applications and end uses for Magic Metal are virtually unlimited. The set up time is 5 minutes and it can even set up under water. Deposits of Magic Metal can even be machined, drilled and threaded.

Handi-Jig Heat Resistant Jigging Putty

This product is every welders dream. Handi-Jig when applied alongside of the weld zone totally protects adjacent areas from heat damage. Its moisture content also acts as a quench keeping heat tint and warpage to a minimum. The jigging applications for Handi-Jig are basically unlimited. Parts in need of repair are easily aligned by simply setting them in mounds of Handi-Jig and adjusting the alignment. Handi-Jig is 100% asbestos free and is totally reusable.

In addition to the standard products, we also offer unique and special products, including:

- Magic Metal epoxy sticks in steel, bronze and aluminum grades

- Handi Jig heat resistant and Jigging putty

Choose a Product Number from the list below to view Datasheets or SDS for that product.