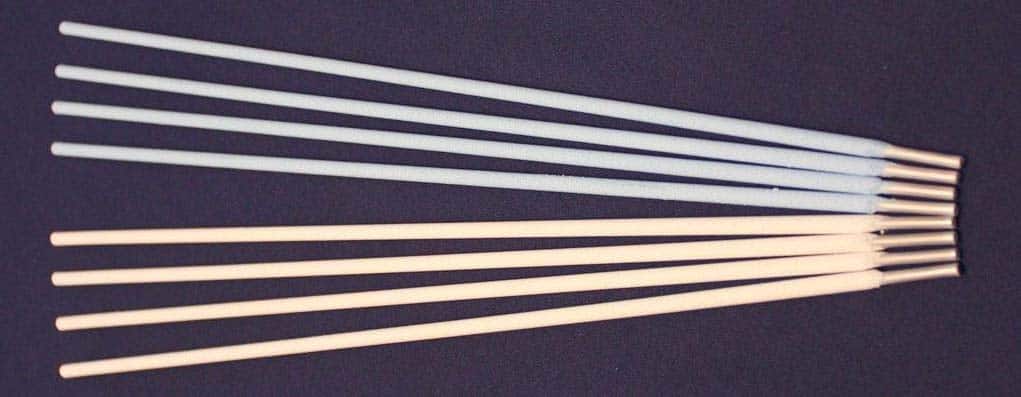

Flux Coated Aluminum Stick Electrodes

As the world’s leading manufacturer of extrusion flux coated aluminum arc welding electrodes, Selectrode Industries specializes in offering all silicon bearing as well as manganese bearing and pure aluminum welding electrodes. Our flux formulation is known to have the very best moisture resistance combined with unusually good arc transfer characteristics. The slag removal is extremely easy and the weld deposit is much more dense than with other type products. A very unique feature of our flux formulation is that it can also be used as a torch brazing alloy.

The already excellent shelf life of our electrode is dramatically enhanced when clients specify packaging in our very own pure aluminium, seamless, pull ring opener can. This can was designed by us to insure that our product can resist moisture absorption especially when stored in very high humidity conditions. This packaging concept equals hermetic sealing with regard to product protection.

As a true manufacturer of these electrodes, Selectrode Industries has the ability to offer custom flux colors with reasonably low minimum production batch requirements. Presently we routinely manufacture these electrodes in the following colors: white, blue, green and yellow. The white and blue are standard stocked items and the yellow and green require minimum production commitments of only 500 lbs. (225 kgs.) Additionally we would entertain developing other new color options per client requests.

Additional Unique Aluminum Joining Alloys

Our very broad range of aluminium welding electrodes is complimented by torch brazing alloys including one of a kind flux coated aluminum brazing alloys and a unique group of low temperature solders for joining aluminum to itself as well as joining aluminum to copper, steel, stainless steel etc. Selectrode manufactures a full range of complimentary fluxes particularly suited to each of these brazing and soldering alloys.

Aluminum Mig and Tig Alloys

Specializing in the manufacture of high volumes of aluminum alloys allows us to offer extremely competitive pricing on a very wide range of both Mig and Tig alloys. Presently we are in a position to supply the following aluminum grades: 1100, 4043, 4047, 4943, 5183, 5356, 5554, 6056 and 6088. The available diameters are : 030” (.8mm), 035” (.9mm), 3/64” (1.2mm), 1/16” (1.6mm), 5/64” (2.0mm), 3/32” (2.4mm), 1/8” (3.2mm), 5/32” (4.0mm) and 3/16” (4.8mm). Spool weights are: 1 lb. (.5kg.), 3 lbs. (1.4kg.) and 15 lbs. (7kg.)

Choose a Product Number from the list below to view Datasheets or SDS for that product.

| Product | AWS/ASME | DIN | Datasheet | SDS File |

|---|---|---|---|---|

| 1190 - 5% Silicon Flux Coated Arc/Torch Aluminum Alloy | A 5.3 E 4043 | 1732: EL-Al Si5 | 1190 | SDS |

| 1191 - 12% Silicon Flux Coated Arc/Torch Aluminum Alloy | A 5.3 E 4047 | 1732: EL-Al Si12 | 1191 | SDS |

| 1193 - Pure Aluminum Flux Coated Arc/Torch Alloy | A 5.3 E 1100 | 1732: EL-Al | 1193 | SDS |

| 1198 - Manganese Aluminum Flux Coated Electrode | A 5.3 E 3003 | 1732: Si-Al Mn | 1198 | SDS |

| 2111 - A Rub-on Solder for Aluminum without Flux | _ | 1707: L-Zn Sn20 | 2111 | SDS |

| 2140 - Low melting Aluminum Solder for joining Aluminum | _ | _ | 2140 | SDS |

| 2190 - Torch Brazing Alloy for Aluminum | A 5.10 ER 4043 | 1732: SG-AL Si5 | 2190 | SDS |

| 2194 - Flux Cored Aluminum Brazing Alloy | A 5.10 ER 4043 | 1732: SG-Al Si5 | 2194 | SDS |

| 2195 - Flux Coated Bead Forming Aluminum Brazing Alloy | A 5.10 ER 4043 | 1732: SG-Al Si5 | 2195 | SDS |

| 2197 - Green Flux Coated Thin Flowing Torch Brazing Alloy for Aluminum | A 5.10 ER 4047 | 8513:L AL Si 12 | 2197 | SDS |

SaveSave

SaveSave

SaveSave

SaveSave

SaveSave