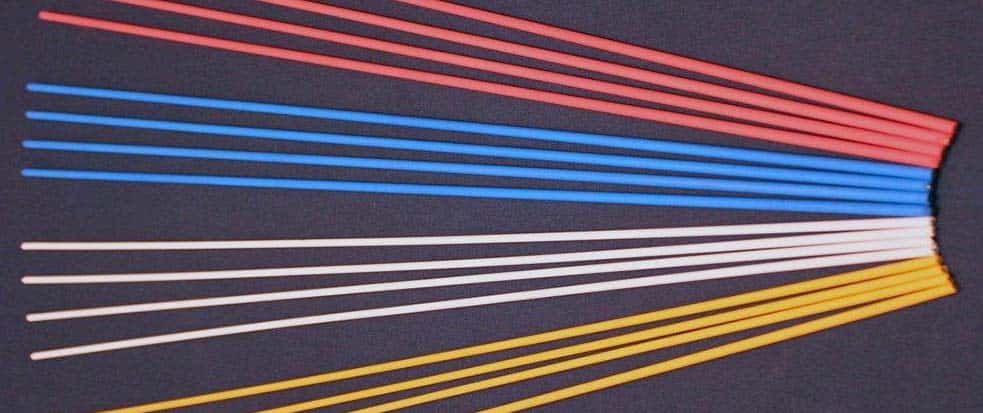

The preeminent brazing product worldwide is the very popular Selectrode flux coated silver brazing alloy. The basis for this successful product is the very proprietary flux coating itself. Typical flux coatings that are flexible in nature are always designed with hydrocarbon bearing compounds that blacken when heated. This blackening effect limits the flow of the molten silver alloy. The Selectrode flux coating formula utilizes a series of binders that are totally free of rubberized agents. When molten the flux is crystal clear and quickly flows throughout the joint area to be repaired. The chemistry of this special flux coating is extremely strong thus allowing for excellent cleansing action on difficult to braze metals such as oxidized stainless steels, tungsten carbide etc. Routinely we manufacture this product with 3 different silver contents: 56%, 45% and 30% in 3 specific coating colors. However as a true manufacturer of this product Selectrode can manufacture any silver alloy chemistry in any coating color with very small minimum quantities.

Our Nickel Silver and Low Fuming Bronze brazing alloys have a flux coating that uses many of the chemical technologies developed specifically for our line of silver brazing alloys. Once again the flux coating is flexible (bendable) but completely devoid of rubberized agents. The alloy flow promoted by these flux coatings is far superior to any other product available in today’s marketplace. Additionally the very special “sodium free” flux chemistry totally eliminates the harsh orange flame glare typically associated with normal brazing alloys. Copper flux less brazing is another specialized area in which our range of copper- phosphorous and silver- copper- phosphorous alloys covers the very wide range of applications encountered worldwide. Lower temperature applications are easily handled with our silver bearing high strength low temperature soldering alloy. This chemistry is available as a solid core, acid core, rosin core or as a paint on paste compound. All of our brazing alloys that require separate flux compounds are associated with specialized fluxes that we developed in order to closely resemble the activity and successful results achieved with their flux coated counterparts. All of the Selectrode flux line can be custom packaged in reasonably small quantities in the unit size of your preference.

In addition to the standard products, we also offer unique and special products, including:

- All grades of flux coated silver alloys in a variety of colors

- High strength/Low temperature solders

Choose a Product Number from the list below to view Datasheets or SDS for that product.

| Product | AWS/ASME | DIN | Datasheet | SDS File |

|---|---|---|---|---|

| 2180 - High Strength Self Fluxing Torch Alloy for Copper | A 5.8 B CuP-2 | _ | 2180 | SDS |

| 2181 - High Strength Self Fluxing 5% Silver Torch Alloy | A 5.8 B CuP-3 | _ | 2181 | SDS |

| 2182 - High Strength Self Fluxing 15% Silver Torch Alloy | A 5.8 B CuP-5 | _ | 2182 | SDS |

| 3110 - Solid Core Silver Bearing Soft Solder | _ | _ | 3110 | SDS |

| 3137 - 30% Silver Flux Coated Orange | A 5.8 B Ag-20 | _ | 3137 | SDS |

| 3147 - 45% Silver Flux Coated Orange | A 5.8 B Ag-5 | _ | 3147 | SDS |

| 3155 - 56% Silver Flux Coated Pink | A 5.8 B Ag-7 | _ | 3155 | SDS |

| 3170 - Blue Low Fuming Bronze - No Glare Flux | RB CuZn-C | S-CuZn40Si | 3170 | SDS |

| 3182 - Red Nickel Silver - No Glare Flux | RB CuZn-D | L-CuNi10Zn42 | 3182 | SDS |

| 5110 - Liquid Soldering Flux | _ | _ | 5110 | SDS |

| 5190 - Aluminum Torch Brazing Flux | _ | _ | 5190 | SDS |

| 6150 - General Purpose Brazing Flux | _ | _ | 6150 | SDS |

| 6213 - Titanium TiG | A 5.16 ER Ti-2 | _ | 6213 | SDS |

SaveSave