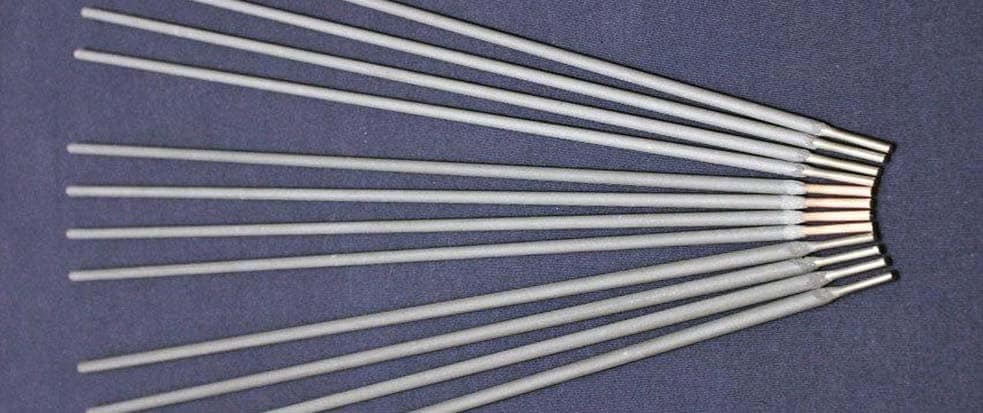

Our all inclusive range of cast iron joining and repairing alloys is very extensive as well as quite unique. Included is our world famous pure nickel electrode featuring a totally non conductive graphitic flux coating. This electrode was pioneered by Selectrode’s Research and Development team specifically in response to those needing the ability to weld in tight confined areas where normal cast iron electrodes with conventional conductive graphitic coatings would side arc.

Our copper clad “TRI-METAL” core electrode is also a Selectrode Industries exclusive. This very unique product totally eliminates electrode overheating and vastly improves joint ductility due to the copper content. This feature is extremely important when maximum weld metal crack resistance is required.

The remainder of our range of cast iron electrodes includes those specifically designed for welding Meehanite, nodular iron and ductile irons as well as those for joining cast iron to steel. This includes our Bi-Metal ferro nickel electrode which exhibits a very strong concentrated arc drive to penetrate deeply into contaminated cast iron surfaces. This strong arc drive also facilitates welding in non horizontal positions.

Our shallow penetration DC- pure nickel electrode features a very soft arc transfer. This feature helps in minimizing the mixing of soft weld metal with the more brittle cast iron base metal. The resultant weld is the softest possibly attainable and is the easiest weld deposit to machine and thread.

Our non-machinable electrode is the ultimate choice for dirty contaminated cast iron repair. This electrode has the ability to penetrate through oil, grease and paint. Usually it is used as a base weld pass to seal the contaminated cast iron surfaces. The final weld repair is then completed using any ferro nickel or pure nickel welding electrode.

Selectrode Industries also manufactures a high quality but lower cost ferro nickel and pure nickel electrode range specifically suited to high volume users that must maintain a competitive price point.

A round bare alloyed cast iron rod is also available for those needing to exactly color match cast iron base metal. There is a great need for this type of color matching repair especially in the machine rebuilding industry and also in the foundry industry where repairs on new parts with casting defects can be blended easily without being visible. A dry powdered flux is also manufactured to facilitate this torch fusion welding process.

Choose a Product Number from the list below to view Datasheets or SDS for that product.

| Product | AWS/ASME | DIN | Datasheet | SDS File |

|---|---|---|---|---|

| 1139 - Bi-Metal Ferro-Nickel Cast Iron | A 5.15 E NiFe-CI | 8573: E NiFe-1 BG 21 | 1139 | SDS |

| 1140 - High Nickel Cast Iron Non-Conductive Flux | A 5.15 E Ni-CI | 8573: E Ni BG 11 | 1140 | SDS |

| 1142 - High Strength Nickel Iron Cast iron | A 5.15 E NiFe-CI-A | 8573: E NiFe-1 BG23 | 1142 | SDS |

| 1143 - High Nickel Shallow Penetration DC(-) Cast Iron E | A 5.15 E Ni-CI | 8573: E Ni BG 12 | 1143 | SDS |

| 1144 - Ferro-Nickel Cast Iron Non Conductive Coating | A 5.15 E NiFe-CI-A | 8573: E NiFe BG13 | 1144 | SDS |

| 1146 - Non-Machinable Cast Iron Non-Conductive Flux | A 5.15 EST | 8573: E Fe-1 | 1146 | SDS |

| 1889 - Copper Clad Tri-Metal Non-Overheating Cast Iron | A 5.15 E NiFe-CI | 8573: E NiFe-1 BG13 | 1889 | SDS |

| 2141 - Bare Grey Cast Iron Torch Rod | A 5.15 R CI | 8573: G Fe C-1-G0 | 2141 | SDS |