![]() View Product Datasheet

View Product Datasheet

![]() View Product SDS

View Product SDS

FEATURES & APPLICATIONS |

A metallic resin that hardens into a tough alloy without any need for measuring its two components.

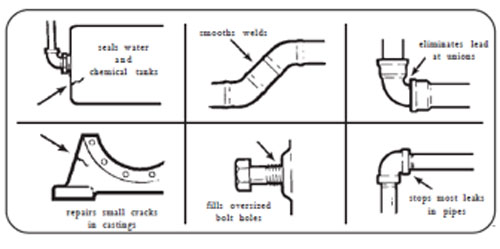

- Unlimited applications requiring a formable metal without heat.

- Available in 3 different alloy types: Bronze, Aluminum, and Steel.

- Hardens in 5 to 10 minutes even under water.

- Chemical and corrosion resistant.

- Can be machined, drilled, and tapped.

GENERAL CHARACTERISTICS:

An extruded metal compound wherein both components are in direct contact with each other. A unique patented process inhibits the hardening reaction until the compound is squeezed and mixed.

APPLICATION:

- PVC

- Cast Iron

- Wood

- Stainless Steel

- Steel

- Galvanized Pipe

- Concrete

- Brick

- Copper

- Brass

- Ceramic

- Chrome

- Aluminum

- Plastics

Typical Mechanical Properties |

Working Time 5 minutes

Compressive Strength 19,000 psi

Max. Operating Temp. 360°F (182°C)

Shore D Hardness 90

Tensile Strength 8,200 psi

Shear Strength 950 psi

Helpful Instructions |

PROCEDURES:

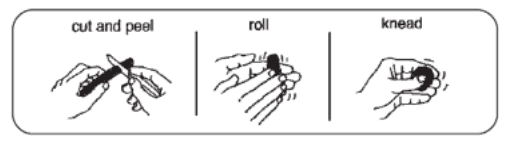

Cut off the desired amount using a scissor or knife. Remove the protective end foil and plastic wrapping. Squeeze or roll the piece between your fingers to initiate the reaction. Mixing is easily accomplished by hand and total mix indicated by observing the blending of the two distinctly different colored components. Apply to area requiring repair and shape as needed. Wash hands in warm soapy water. Reapply protective end foil and store resin in its original package. Repaired area can be machined in about 20 minutes if required.

Alloy Type Part Number

Bronze 8000

Aluminum 8100

Steel 8200