![]() View Product Datasheet

View Product Datasheet

![]() View Product SDS

View Product SDS

FEATURES & APPLICATIONS |

A dramatic solution towards eliminating long hours of hard surfacing.

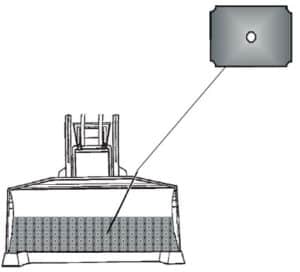

A dramatic solution towards eliminating long hours of hard surfacing.- 4″ (100mm) x 6″ (150mm) X 3/16″ (5mm) thick.

- Metallurgically formulated to give a hardness of Rockwell C60 throughout.

- Special “Black Chrome” finish yields an exterior skin hardness of Rockwell C72.

- Center & corner plug shape allows for easy attachment with our special Diamond Join electrode Code 1247.

- Cost-efficient – the speed of application reduces cost and down time. Discs can be replaced individually, as needed.

- Labor and Time efficient – much faster application than weld overlays.

The Advantages of the Diamond Disc® Wear System:

Verses Weld Overlays:

- Diamond Disc® can be applied in about onetenth the time of manual arc welding and about one-quarter the time of semi-automatic welding.

- Diamond Disc® has a constant hardness of Rockwell RC60 for the total 3/16″ thickness. Weld deposits will vary due to base metal dilution.

- Diamond Discs® do not affect the base metal because excessive heat is not used during application. The high heat sometimes used in welding procedures may cause a reduction in mechanical properties of the base metal.

Verses Other Weld Plates:

- Diamond Discs® are a manageable size, easy to store and transport

- Diamond Discs® are one convenient size. 4″ (100mm) x 6″ (150mm) X 3/16″ (5mm) Thick. Reducing the need to stock many different sizes.

- Diamond Discs® can be applied in about half the time of other wear plates, saving time and money

- Diamond Discs® weigh about half that of other plates, so there is less stress on the operating systems.

- Diamond Discs® can be replaced individually, not the complete wear plate.

- The Diamond Discs® application pattern creates compact spaces between discs increasing abrasive wear performance.

APPLICATION:

- Bulldozer Blades

- Mixing Paddles

- Shovels

- Scraper Blades

- Excavator Buckets

- Screw Conveyors

- Slides

- Bulldozer Track Idler Wheels

- Chutes

Welding Current & Instructions |

INSTRUCTIONS FOR USE:

Clean weld area with a wire brush. Make sure the area to be protected is smooth and flat. The entire perimeter of the Diamond Discs® should be in contact with the base metal. Arrange Diamond Discs® in the desired pattern. Plug weld the Diamond Discs® to the base metal using a fillet weld around the circumference of the center hole using the specially alloyed 1/8″ (3.2mm) Diamond Join Electrode Code 1247. Also join where the four corners of adjacent plates meet forming a similarly shaped plug area.